New Approaches in Structural Concrete Waterproofing

New Approaches in Structural Concrete Waterproofing

Webinar Show Notes

Waterproofing Systems (the download referred to in the presentation) markhamglobal.com/markham-videos/concrete-waterproofing-systems

Complete Basement Waterproofing markhamglobal.com/complete-basement-waterproofing

Waterproofing Concrete Roof Decks markhamglobal.com/waterproofing-exposed-concrete

Learning Outcomes

- A holistic concrete waterproofing system

- A range of benefits including concrete crack control

- End-to-end approach and performance-based warranties

HENRY: Welcome today! My name is Henry Mitchell. We’re here to talk a little bit about concrete waterproofing. I’ve been with MARKHAM for about nine years now. I’m very passionate about waterproofing concrete itself. On the line today, I’ve got Ben Dowell. Tell us a little bit about yourself, Ben.

BEN: Thanks, Henry! Good to be on board today. I’m based in Perth, Western Australia. We’re currently in lockdown, so excuse me if any children or anything run past in the background. But yes, I head up the sales and operations for MARKHAM in Perth, Western Australia. I’ve been with the company for about three years now. Looking forward to sharing a bit of our knowledge about the way to waterproof basements.

HENRY: Awesome. Thanks, Ben. Thanks for the early start, mate. What we want to talk about today is MARKHAM. You’ve probably seen our marketing out there and what we’re about; we’re about sustainable treatments for concrete. But today, we wanted to narrow that down and just talk about the new setup for basement waterproofing. We’re going to cover three parts: obviously, the system; the benefits around crack control; and the end-to-end approach with performance-based warranties.

So we’ve just got a little poll here to do for a start, just to get a better idea of where you guys come from and what you’re about. If you just click on that, and we’ll get the answers up, just so we can make it a little bit more focused for you guys. Awesome! I see that 71% of you are interested in new and advanced technologies. That’s awesome, so we’ve got to help you out and show you some new ways of doing things today.

First off, I just want to go over the system. This is not a new product as such, it’s been around since 1985 – these systems have. But they’re new education for a lot of people, so that’s where we’re going to help you.

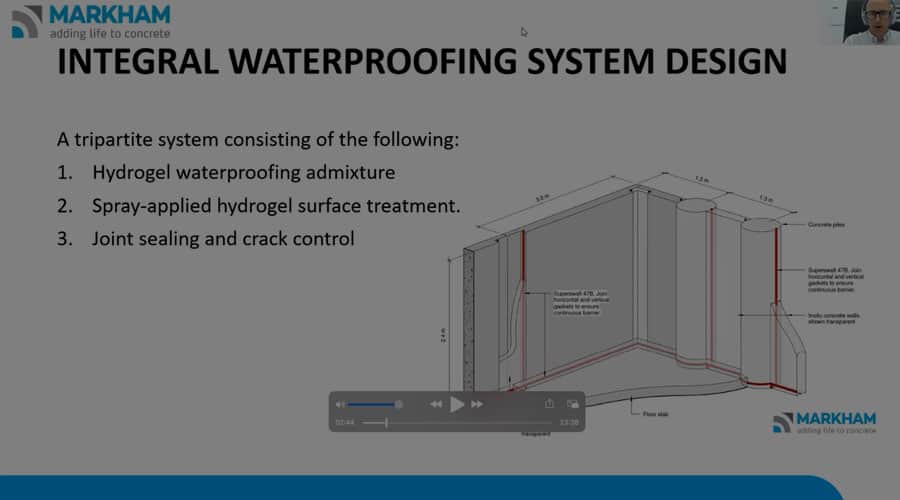

The MARKHAM waterproofing system is basically made up of three parts, or four parts as I like to call it. So first off, we talk about waterproofing the concrete itself with admixtures. Secondly, we get involved in spray-applied secondary waterproofers and cures, penetrating sealers. The main part here is addressing the joint sealing and the crack control, because that’s our weak point as such. But the fourth one—that’s not on here today, and which we’ll cover off further in the presentation—is the QA and the warranty, and getting involved at the design stage and working right through the process. So then we can give your clients a 25-year+ performance warranty.

Before we get into how we do it, I just wanted to show you a couple of snapshots of different projects across New Zealand and Australia where we’ve worked. Moving a bit close to my hometown, Palmerston North. So this was a 12-metre dive pool that the Air Force use in Palmerston. They’ve got a helicopter sort of cage, they chuck in there and they do rescue moves on it, which was quite interesting to watch. But the interesting part here was, this pool is such—which it can be classed as the same as a basement—it was 12 metres deep without a membrane on the inside or outside. So you can see a really awesome example; we’re stopping the moisture from getting out, but also stopping any hydrostatic pressure coming in as such. Tell us a little bit about this one, Ben.

BEN: Thanks, Henry! So this one here is The Glen Shopping Centre in Melbourne, Victoria. We were called to provide some waterproofing to the car park decks above retail shopping. I believe another system had failed here. It was quite a high-risk sort of setup. There was obviously a David Jones and MYER’s and the likes below. So what we were able to achieve here is total waterproofing using the hydrogel systems. This had the admixture dosed at the plant, then the spray-applied after pour for curing and an extra line of waterproofing. Then as you can see in that bottom picture there, is the black polymer waterstop gasket in the construction joints there. I think you went to this site, didn’t you, Henry?

HENRY: Yes, awesome. Thanks for the update, Ben. I visited the site when it was about stages one and two had been finished. The whole project was the biggest admixture project in Australia at the time, I think it was a total of 25,000 square metre car park. They had some record storms there about three years ago, and that really stood the test of time. It was awesome to see the full system working in that area.

BEN: This one’s a bit closer to home. This is in Perth, Western Australia. So what we were required to do here is fully waterproof and provide tanking in the concrete for the basement. It was quite a tricky project. As you can see in the middle there, there was a heritage-listed house which had to be preserved.

Basically, for this project, we provided the hydrogel admixtures in the concrete to the slab on-ground in basements, so that was all dosed at the plant, as well as the shotcrete to the piles… to cover the piles. So we had admixtures in the shortcrete, and then the slab on-ground, and then we had the spray-applied hydrogels at the time of pour for extra curing, and line of protection of waterproofing. This also had the swellable gaskets to all construction joints. So wherever concrete met concrete, we applied the waterstop gasket.

This project was a success, and to date, we haven’t had any problems with it. It was a very good project to be involved with, and we also saved the client a lot of money. So we basically turned the concrete element, which is already needed and incorporated in the build cost, into the tanking system, negating the need for any external membranes.

HENRY: That’s awesome, Ben. Thanks for that update. So just moving a little bit close to home for myself again. It’s interesting you say that Ben, about saving the client money. This project actually here aligns exactly with that principle as well.

Westfield had the original waterproofing package in their basement car park and car park; it’s about 1.5 million I think, for this new shopping mall in Auckland. We saved them about a million bucks in their waterproofing package. So we came in under $500,000 to waterproof, cure, and anti-dust their whole car park there, which is a massive cost saving obviously as you can see. There’s also other hidden cost savings. The concrete turns up to the site already waterproofed, as such you don’t have to have the lengthy delays of a membrane install, or wait for … or the chance of it getting damaged. So big plus there for Westfield, you could see the time savings and the cost savings there. Really cool mall! If any of you are in Auckland, be sure to visit there. It’s a brand new mall, and at the top, there’s a full on rooftop bar and gardens. Quite a neat place to spend a Saturday afternoon.

But we’ve talked about the projects, now we just wanted to talk a little bit about how we do it. So we’re all about hydrogel technologies. So these are nanotechnologies that get inside the concrete, whether it’s spray-applied or admixed into the concrete; we’re not introducing anything foreign here. It’s a sustainable source product, so we can tick that box from Green Star as well for you guys.

How it works is, basically all the free moisture that usually moves in and out of your concrete and causes the problems, we just immobilize that into a gel. Your pores and porosities are filled up with that gel, which can stop moisture migration going in and out of your concrete, and therefore, also stop hydrostatic pressure. So below water tables, basements, that sort of thing, we have no problem working alongside your builders and your architects to give you a performance-based warranty.

Again, you’ll see this cross-section of the concrete pour, the blue obviously representing the moisture that moves in and out of the concrete. With the hydrogel treatments, it immobilizes that moisture so there’s no chance of moisture moving in and out of the concrete. We’ve studied concrete with other doctors and concrete engineers and professors around the world for the last 25 years. The biggest conclusion we can find is if you can stop moisture migration in concrete, you can stop a lot of problems. That’s what we’re all about. Tell us a little bit about the weaker risk areas there, Ben.

BEN: Thanks, Henry. So I’ll go into the actual gasket which we use in all cold joints or penetrations; you can see there, the blue wrapped around the penetration there. So the CONQOR 47B and 87B Waterstops are unique sealing gaskets that expand in a controlled fashion when exposed to moisture, forming a compression seal in concrete joints. CONQOR Waterstops have superior durability and weather resistance during construction, as compared to clay-based waterstops.

This is because the waterstops are actually a polymer-based product. So as I said earlier on, they don’t expand quickly, whereas the clay-based and bentonite strips expand real quick onsite if they’re exposed to moisture before they’re covered in concrete. This polymer waterstop only requires 50mm cover, whereas some of the others require 90mm. So it can be used in thinner wall space. That’s about it for that one. Thanks, Henry!

HENRY: Thanks for the update on the gaskets. Compatibility!

BEN: Compatibility! So this one is where probably the hydrogel admixtures shine in quite a way. The fact that they are colloidal silica-based, so it’s out of the cementitious family. So we’re not actually adding anything foreign to the concrete matrix. So your line-markings, epoxy coatings, floor covering adhesives, and any other product designed for bare concrete, will adhere to the concrete. With the hydrogel technology in the concrete, it actually provides a stronger surface so you don’t get dusting on the surface; you actually get a better adhesion for anything that is being applied to the surface of that concrete.

HENRY: That’s awesome, Ben. Thanks for that update. Keep the questions firing through, team, if you’ve got anything on there, we’d be happy to answer those in a couple of minutes. Crack control!

BEN: Thanks, Henry. So crack control is another vital component of waterproofing concrete when we’re relying on the concrete itself to be the waterproofing element also. So as you can see in those two pictures there, the membrane for the surface, either inside or outside of the concrete, only achieves between 2–5mm penetration, and then you’re relying on the actual membrane itself to do the job.

Whereas the hydrogel is complete, all the way through the concrete matrix. With it reacting with the moisture in the concrete, it basically locks that moisture in the concrete as a gel. So at the time of pour, that moisture can’t evaporate causing shrinkage, and therefore leaks. We also have 0.5mm self-healing properties. Because it is a cementitious product, it will actually self-heal up to a 0.5mm crack, if and when it does occur in the concrete. I don’t know if you had anything more to add to that one, Henry.

HENRY: No, that’s pretty good, Ben. These diagrams here obviously illustrate that when we spray-apply our hydrogel systems to the concrete, we can get up to 150mm as chemically attracted into the concrete. So even when I’ve worked on wharf structures underneath, we spray up on the underside of the wharf deck and we can still get that penetration because it pulls itself in the concrete. Over against just a surface hardener that is a thin lid that over time will break down, giving you soft concrete underneath.

But moving on now to performance warranties. So we’re a very risk-averse company; we like to work from design through to installation. The only reason why we can pass on these 25 year+ performance warranties is that we’ve got a little bit different model to a lot of other people out there, where we keep very tight QA control the whole way through. So we work with the architects, get the detailing sorted. We go to the ready-mix plant, we make sure that’s mixed to the right standard. We go and QA and check off any gasket before any concrete is poured as such. Also, our guys are spray-applying the cures and that sort of thing. So they’re all employed by us, there’s no middleman as such; there’s no hardware or software. It’s straight between us and your clients.

Then you’ll see a quick diagram there of the likes of what you’d get from our QA team. You’d get a markup of the plan. You’d know where the admixture has been mixed, what day it’s been mixed, who QA checked it off. You’d know who signed off the gasket. You would know who spray-applied the penetrating sealers and cures, and it’ll be a marked back to a gridline. So in essence, it’s reducing the risk for the system, one point of contact, and then we can pass those warranties on to you guys.

So one last thing we like to talk about is a historic project here at MARKHAM. This project was in 1997, built at the Canterbury Maths and Science University beside a river. This basement had a failure through the construction process. So obviously, you had about 200–300mm of water coming into that basement. I’m not sure the exact reason why or how or when or what the deal was.

But in essence, the construction company got us on board, and we pumped that water out, sprayed our hydrogel treatments to the surface so wet on wet, and that helped to get into the concrete. We self-healed about 1,000 lineal metres of cracking, and we had to inject about 500 lineal metres that were above the 0.5mm threshold, which was a really really cool example of how the hydrogel works. It’s a little bit different to the new basement setups we’ve been talking going through, but it still shows you how we can waterproof existing concrete as well just by purely stopping the moisture ingress in and out of concrete.

So that’s getting close to a wrap. Now, there will be a download available on follow-up email. But that’s a quick overview of our concrete waterproofing system. Alternately, actually, we’ll send you an email, but you can if you’ve got time to flick either my email or Ben’s down, and you can fire us an email and talk about a project. As we’ve said, we’re very project-specific. So I’ll just turn the screenshare off and we’ll answer some of your questions.

Awesome. So what have we got here? We’ve got a couple of questions. So the first one, Ben, is an interesting question. Can the water trapped inside concrete cause corrosion of the reinforcement? That’s an interesting question, a very good question. Because I think you’ve got the concept of how the hydrogel works. But just a little twist on it, we don’t trap water inside the concrete, we transform it into another state. So it’s no longer moisture that can move in and out of concrete. So, therefore, we stop the chance of corrosion in reinforcement; we’re protecting the steel, which I guess is the essence of waterproofing concrete is to keep our structural integrity by stopping our moisture from getting to our steel.

BEN: I’m also going to add to that, Henry. Because we’re working internally and throughout the complete concrete matrix, it negates or stops any air reaching the reinforcement as well. So our theory is, if we can pull one of those elements out of the corrosion process, it’ll also stop it from happening.

HENRY: Yes, that’s awesome. You see that in wharf structures, don’t you? So below the tidal zone that the pile can look just about brand new, but in that splash zone, that’s where all the corrosion happens, because it’s got the oxygen, it’s got the moisture; it’s got the three things to keep that process going. So by cutting out one of the areas, we can limit that. There’s another question there. How do the properties of sealing materials change with time? So you can probably answer this, Ben.

BEN: It is a very good question, I think. Because the hydrogel is colloidal silica based, and of the cementitious family, they are set up in the concrete matrix for the usable life of that concrete. So once they are in the concrete, they can’t be destroyed unless it is the concrete itself that’s destroyed. Over time, the hydrogels will actually grow and become part of the Calcium Silicate Hydrate. So they will become part of the actual concrete, and set up the matrix as well. So what we’re basically adding is more of the good stuff of what concrete paste is into the concrete, in those pores and capillaries. I don’t know if you had any more to add to that one.

HENRY: No, that’s a good insight. I couldn’t do better than that, Ben. There’s one more question there. Any reinforcement ratio requirements? How to answer that? So we just have a positive effect on the engineers’ design from a structural point of view. So we don’t say you should take out steel or we should add more steel. One side note around that, there are admixtures out there that decrease the strength so you have to add more steel. But because we’re not adding anything foreign to concrete, we’re just adding more the good stuff, we just have a positive effect on the structural design as such. Hopefully, that answers that question. We’ve got another one.

BEN: The only thing I probably would add to that one is, because we work heavily in providing equal to 14-days water curing, the early strength goes up with your concrete.

HENRY: Yes. Does the hydrogel work effectively with old concrete blocks? Interesting one. We’ve actually got a system called AQURON 3000 that forms a thicker gel. It’s not something we get involved in that much; concrete blocks are a hard one to waterproof, especially old ones because you’ve got so many variances. One, they’re very porous. Two, you’ve got grout lines. Three, where do you stop and start if they’re put bang on a slab as their gasket line, that sort of thing? So that’s where, as a risk-averse company, we’ll steer away and say, we think that you should probably go with a belts and braces like a membrane of some sort. So hopefully that answers your question, Mark.

There’s one more question there. Can the sealing material create extra pressure and cause cracking of concrete? Let me think about that question.

BEN: That is probably a pretty good question. I think maybe what he’s asking there is, because we are forming a gel in the concrete, are we producing any extra pressure within the concrete matrix? So what I was going to say to that is, all we’re doing is trapping any moisture which is already in that concrete, and locking it in the concrete. So we’re not introducing any other components into that concrete.

HENRY: Another side note I’ll add to that, Ben, also would be that, like some of the admixtures, they pull all the moisture from the concrete around it to feed the crystals as such. But with the hydrogel, we’re actually feeding the hydration process of the concrete. So we get better curing; better curing equals less shrinkage, more hard and durable concrete from day one. So we’re minimizing shrinkage as well, and then we’ve got the self-healing ability to self-heal any cracks if they do appear.

Concrete does funny things. That’s why every project is a little bit different, and that’s why we get involved early on. We can also talk about things like saw cut layouts and control joints and all that sort of thing.

But hopefully, that’s answered your questions. We’re just about on time, 11:26. So thank you very much to everybody that’s joined today. We appreciate your time in this busy schedule. If you have got a project, fire me an email, fire Ben one, we’ll be happy to help you out and discuss it. Thanks very much, and we will see you next time.

BEN: Thank you very much all.

More about MARKHAM

MARKHAM are dedicated to providing innovations for concrete and construction. Focusing on concrete waterproofing solutions, penetrating concrete sealers and durability treatments concrete.