Resist Attacks in Concrete - The MARKHAM Interview

Resist Attacks in Concrete – The MARKHAM Interview

Webinar Show Notes

Resist Attacks! markhamglobal.com/safe-concrete-treatments-for-water-infrastructure-2

AQURON Insider invisible-strength.com/podcast/aquron-insider

Learning Outcomes

- Why the concrete often doesn’t meet its planned design life?

- How is cracking a problem for durability?

- Does painting a coating onto the surface protect the structure from attacks?

- How to protect the concrete and make it more durable?

CHARLES: Kia ora and welcome everyone! It’s great to have you all on board for today’s MARKHAM Interview. My name is Charles Currie, and I’m part of the support team here in Napier, NZ. Today we’re going to visit Hayden Prestidge, our Sales Marketing Manager, who is currently out and about. Kia ora, Hayden!

HAYDEN: Kia ora, Charles! Thanks for that. Hope you can hear me and see me okay out here. It’s a beautiful day in Napier today where we’re coming from. But yes, pleased to be on this. These webinar sessions have been really good; educational, short, sharp. So I’m keen, take it away.

CHARLES: Awesome. Our core topic today is, Resist Attacks, and what we’re specifically talking about is resisting internal chemical attacks within the concrete. I’m going to be hitting Hayden with some questions around the issues he sees out in the field, and the MARKHAM systems and approach to these issues. We’re then going to open the door to audience questions later in the presentation. So please feel free to use the Q&A button at the bottom of your screen in the middle there. Fire us some questions as we go along, and we’ll come back to you a bit later on.

Let’s get the show on the road. Hayden, we’ve talked in some of our previous webinars about the unplanned costs of maintaining concrete infrastructure. Are you able to give us some background and why the concrete often doesn’t meet its planned design life?

HAYDEN: That’s an interesting way of looking at unplanned costs. I guess what we’re seeing in the industry is, we’re planning these structures and we’re designing these structures, and from a structural point of view, that end up designed perfect; the strength while it’s loaded out, what’s going to be working on the structure, what’s the flexural strength, what’s required of that structure itself, etc.

But what’s often unplanned or not being looked at in detail is what the environment or what the situations can throw at it, so what the attack might be. See, I’m close to the sea here at the moment, and that’s chloride attack; that’s salts. You might need fertilizer, or you need acid attack carbonation under car parks, these types of things. That’s often not being planned for, that level of protection, what’s needed, and also through those stages.

Like, we might plan a good structure, good cover, plenty of concrete, good strength concrete. But what about the curing process, is it done right? Does it lead to things where you might get microcracking, and a series of events that might happen that hasn’t been planned for, that might lead to premature deterioration? Does that make sense? So, I think from a structural point of view, it’s well planned and well designed. But what can the environment throw at it, these attacks, is probably what’s being unplanned, and that’s probably not being looked at close enough.

Interesting enough, the Australia Concrete Repair Association pulled out a document recently, it’s on the screen now. But basically, in short, if you spend $1 in that planning stage of resisting attack or some preventative maintenance at that point, $1 could result in a saving of $125 later down the track. Because you’ve moved through your phases, you might get through to corrosion, and you might end up having to rebuild that whole structure. So $1 versus $125, obviously, take that out into millions or multi-millions as the structures are now. If that makes sense, Charles?

CHARLES: Yes, that’s massive. Thanks for that! Are you able to dig into that a little for us? How is cracking a problem for durability?

HAYDEN: Yes, so I mentioned cracking. Concrete takes on moisture regardless and needs to be protected, but where cracking comes in is, it accelerates that. So if we get things slightly wrong either in the design or in the placement of concrete or in the curing of concrete, and it gets some cracking through the concrete, that accelerates that whole process of letting moisture into the concrete. Basically, if you can stop moisture coming into the concrete, you’re stopping 99% of concrete issues. Because the moisture brings in chlorides or contaminants or acids; these things that attack and react inside the concrete and result in that corrosion cycle starting early. Like we say, premature deterioration, so it’s unplanned and it’s not resisting the attack.

So from a cracking point of view, it’s really just accelerated allowing the moisture to get straight into the depth of steel. That’s a level you want to protect, and so you want to stop getting through to there. Does that cover that?

CHARLES: Yes. Just so that I’ve understood you, what you’re saying is, bad reactions happening inside the concrete long before the deterioration is obvious? Is that correct?

HAYDEN: Absolutely, it can happen like that. In our industry, it’s referred to often as concrete cancer. Now hopefully, that doesn’t offend anyone on the call today. But if we can just look at it as an analogy, I think we’ve all been close to someone with cancer. So if we think of that analogy of it, it’s that it might be working away inside, and then all of a sudden, it pops out on the surface or something becomes really obvious; same with concrete. You have a corrosion cycle working away inside; you can’t see it. You’ll have moisture in there. You’ll have chlorides in there. You’ll have an acid attack. You’ll have silica reactions going on. Then all of a sudden, it pops out. It might be in a big breakout, some spalling might be in some rust staining, all those types of scenarios.

So yes, it is something we see a lot actually. Because you do a visual inspection of a project or a structure, and it looks perfect on the surface. Dig a little bit deeper, take some tests at the level of steel, things like that, and there’s big reactions going on that need protecting against. So that’s a good point.

CHARLES: So if we paint a coating onto the surface, will that protect it?

HAYDEN: It will protect concrete to a point, and I’d just like to emphasize “to a point.” Because a coating is a bit like putting a sticky plaster on a sore. It’s still acting inside there; all you’re doing is protecting the surface. It might even still be infecting under there, it might be working away and doing its damage underneath, but you’re protecting the surface.

Whereas that’s okay, and it might stop new moisture coming in, or mud or dirt or whatever it is in a plaster scenario. But with concrete, if you get some sort of coating or painted surface, all that needs is some wear or some gap that’s missed, and moisture can come straight back in there and it wears off over time. If it’s a hard-wearing scenario like a port structure or even a big tank where you have got running water, it’ll wear off the sides, and before long, you’ll have to be re-coating it and recoating it and recoating it. So it’s like a maintenance thing.

One other thing with coatings is, you’ve protected the surface, but inside, the chlorides and the moisture is not been immobilized; it’s still working, and still, the corrosion cycle is going on. So it’s almost like you’re sweating inside a rain jacket; that type of analogy.

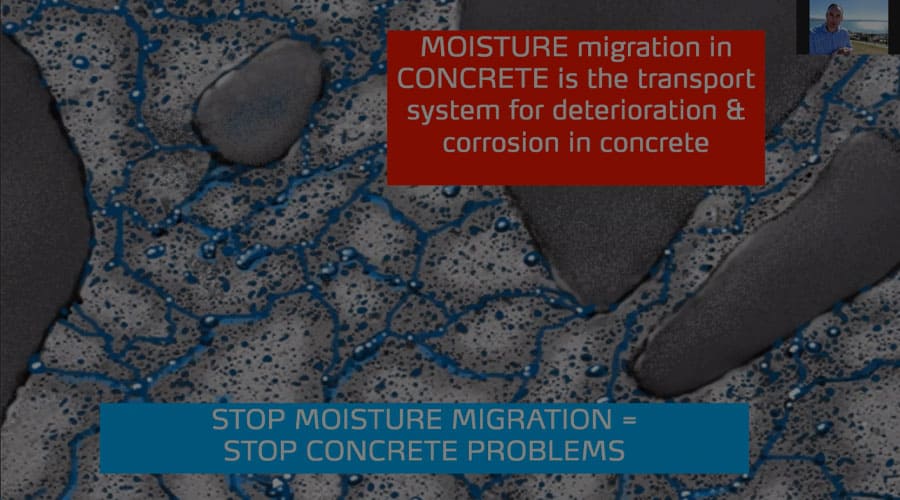

This slide is interesting, and it probably might show better what I’m referring to. So this is now looking right inside the concrete. You can see the big grey aggregates there, the stones. Then the lighter grey aggregates, that’s your Calcium-Silicate-Hydrate; that’s your cement particles, and that’s the binder of your concrete. Then you see these blue roads or capillaries in there. Now, what they’re from is, when concrete is new, only a portion of the water that’s actually mixed in with the concrete at the start is used, and it bleeds back out. So it comes back out through the surface or underneath, and it leaves these channels, these roads, or these capillaries that need to be protected.

So what I was saying is, if you coated that top and moisture was still in there, it’s still very active inside the concrete. Also, if you wear it, again, you’re just allowing the opening up more and more channels. So does that make sense?

CHARLES: Yes, it sure does. So what is the best option, how do we get inside the concrete and protect it?

HAYDEN: MARKHAM have utilized a lot of systems over the years, but one that’s come really strong is our penetrating hydrogel system. So if you just envisaged that slide that I was looking at earlier, being able to penetrate the concrete with it – with a product that goes in, reacts with the moisture, and gels off to protect those pores or capillaries – that’s what we’re doing with our hydrogel product.

So you might have heard of us talking about AQURON hydrogels, if anyone’s been on earlier webinars. That’s what it’s doing inside the concrete. It’s going in there, going in those capillaries or pores and forming a hydrogel, and that hydrogel protects moisture migration. So that’s permanent right inside the concrete; it can’t be worn off, and it immobilizes your chlorides and it immobilizes the attack, if you follow.

CHARLES: Yes, that’s great. What sort of situations or projects does that best suit, Hayden?

HAYDEN: A vast range of projects. Obviously, we’ve talked a little bit about marine today, that’s a big one. But then moving through into even car park structures with carbonation; even just waterproofing of basements, that type of scenario. You might have contaminated soils. Wastewater is a big one with that acid attack; there are fertilizer attacks and things like this. They are very harsh environments, even through to the aged care where you get urine and things getting into the concrete. So it’s a whole range of projects really. Concrete in general does need protection; it does need something to keep its design life.

CHARLES: Yes. Hydrogel treatments can also be used for reparation of structures as well, is that right?

HAYDEN: So you mean like some repairs done and then protected, is that what you’re thinking?

CHARLES: Yes.

HAYDEN: So in a lot of structures that have got corrosion cycle started, the repairs may be needed. Often, it’s like a breakout repair, more concrete around it and things like that. But if you haven’t got to the core of the problem, what happens is you’ll get corrosion starting right beside where it was. So the patch might remain well, but because corrosion was already working inside that structure and inside that concrete, it will just break out beside it, and before long, it’ll just keep moving. Now, if you’re a repair contractor, that’s brilliant, because you get repair work running through. But as an asset manager, or as a designer, that’s not what you want to see.

So utilizing the penetrating hydrogels, you can get into the core of the problem, particularly at that level, and you’ll stop that breakout further on. So absolutely, protect repairs, protect before you put the repair on to the concrete underneath and your repair, and you’ll have a long-standing structure.

CHARLES: That’s awesome, excellent. Thanks very much, Hayden. I appreciate you taking the time to help us understand that, and I can see how it would save a lot of time and money in the long term.

We are now going to move to question and answers, and it looks like we’ve got a couple that have just come in. The first one is, When do you apply the gel, and what’s the effect on concrete curing?

HAYDEN: Brilliant, that’s a good question! I probably haven’t covered that enough. So there’s two ways of doing it. If you’ve got an existing structure, we can apply it to any age concrete; we just need access to the concrete. So we’ll still get that depth of penetration, we’ll still get that protection.

Now where it’s unique, and where it’s really beneficial to a project, is apply it as a cure. So as soon as the concrete is poured, insitu slab or precast panels, and that needs curing anyway. Water curing is like a benchmark. But practically, it’s not very possible on most sites now to get a decent water cure. So we use a hydrogel, and it sprays on, and because it goes in and transforms that moisture to a hydrogel, it retains that moisture in the concrete, and that’s what you need to do for quality curing. It keeps feeding the cement, it makes the concrete stronger to last longer right from day one. The performance of it is equal to a 14-day water cure, and that’s moisture retention. So that’s a good point, thanks for asking that question.

CHARLES: Awesome. The next one is, How long is the standard warranty?

HAYDEN: That’s good. MARKHAM is a very project-specific company. Every project is different. Every situation is different. Every environment is different. You might take a wastewater scenario, just a waterproofing scenario, or a chloride scenario. But on standard, we provide a 25-year warranty as a standard warranty, and it’s a performance warranty. It might be around stopping chloride ingress, or it might be about water penetration, or it might be around the loss of cover. So we’re measuring these sorts of things. But yes, that’s our standard warranty, and it really only grows from there.

CHARLES: That’s good, thank you. Another one just came in now. Do you have any test results to confirm the long-term durability performance of this product?

HAYDEN: Yes, absolutely. Whoever asked that, if they want to share some more information on what type of project or environment they’re working on…? But yes, absolutely, we do a lot around testing of our solutions: penetration tests, chloride diffusion, these sorts of things. Ultimately, we can see what and how it affects durability. But the main thing there really is stopping that moisture, you’re making the structure more durable. That’s a great question. Feel free to email me afterwards, some specifics on that, and I’m keen to help out there.

CHARLES: Awesome, that’s good. Well, it looks like we’ve just got one more. How often does it have to be reapplied?

HAYDEN: That’s a good question, sorry I didn’t touch on that earlier. So we touched on like a paint scenario or coating scenario; they pretty much have to be a maintenance contract, you have to keep doing that. Where this AQURON hydrogel is unique is, once it’s gone into the concrete, once it’s transformed to hydrogel and it’s working inside the concrete, you can’t reverse it and you can’t get rid of it. So nothing else can break it down, because really, it’s just creating more of the Calcium-Silicate-Hydrate, and nothing’s going to break that down. So it’s really a permanent treatment. We’ve done a lot of projects over 20 years that haven’t needed to be recoated. It will last for the length of the concrete structure, if that makes sense.

CHARLES: Yes, that’s great. Another one here, How would you use this on existing water retaining structures?

HAYDEN: Yes, that’s good. Because the really neat thing about that is, say you’ve got a live reservoir or drinking water or something like that, that you can’t take it offline, being able to penetrate the concrete so much, you can treat your structure from the outside or the inside, whatever way you like. Say, in a basement scenario where you’re retaining water from coming in, you can treat a wall from the inside and get that penetration and get that performance. From a tank scenario, you can treat it from the outside, and we might have some seepage and you’ll get that. So really good from water retaining on existing, we’ve done a lot of that, combined with repairs that may be needed, joints etc, and then particularly concrete as well.

CHARLES: Awesome, thank you. Looks like we’ve got time for one more. How long has this product been around for, and have you got any example of success in recent times?

HAYDEN: Yes, absolutely. So we brought this product to Australia and New Zealand in 1996, and we’ve been treating structures ever since that point. So there’s a lot of track record on a vast range of projects. So we’re treating around 150,000 square meters a month now, and that’s across curing, sealing, and then we’re talking car parks, tanks, wharves, even bridges; everything concrete. So yes, huge project range. If there were some specifics on that question, I’m happy to share some actual projects that may be aligned with what you’re working on. But yes, absolutely. Jump on our projects page as well on the website, you’ll see some good history on the type of projects we get involved with.

CHARLES: Yes, that’s great. Thanks very much, Hayden. Was there anything else you wanted to share with us before we close?

HAYDEN: No, that’s good. Unless anyone’s got any more questions. But no, it’s been good, it’s a good topic. Resisting the attack is always good preventative maintenance. Extending service life is our catchphrase if you want, because we want to buy time; we’re making the world actually more sustainable by not having to reuse more concrete, more new builds, etc. So that’s good.

CHARLES: Yes, that’s key. There is just one more that’s come through. Do you undertake remediation works or just supply these products?

HAYDEN: We can, and we’ll be interested in looking at that. We work with teams closely associated with us, and we can carry out whole repair works. So we do that on like big car park structures, wharf structures, tanks, tunnels is a big one where we maybe get underneath; we’ve done a lot into the hydro sector, things like that. So yes, absolutely. Keen to look at that.

CHARLES: That’s awesome. Well, that wraps up for today. Thank you very much everyone for coming on board, and we look forward to seeing you next time. Have a great day!

HAYDEN: Brilliant! Thanks all!

More about MARKHAM

MARKHAM are dedicated to providing innovations for concrete and construction. Focusing on concrete waterproofing solutions, penetrating concrete sealers and durability treatments concrete.