The Challenge of Marine Concrete

The MARKHAM Interview – The Challenge of Marine Concrete

Webinar Show Notes

Durability markhamglobal.com/solutions/concrete-durability-treatments

Marine Structures markhamglobal.com/special-needs-marine-structures

Photo by Michael on Unsplash.

Learning Outcomes

- Challenges faced by marine concrete.

- How can these challenges be met?

- For which other structure types is this relevant?

CHARLES: Hello all! And welcome to today’s MARKHAM interview webinar, on the challenges of marine concrete. I’m Charles Currie, based in the Napier NZ office… Currently on my last day of working from home due to NZ lockdowns!

Today I’m going to be interviewing Doug Hamlin, our R&D Manager in the MARKHAM Infrastructure and Industry Department. Doug, would you like to introduce yourself?

… You’re on mute!

DOUG: Sorry, I thought I would have got used to that by now! Yes, likewise I’m just coming out of, we’re obviously coming out of lockdowns in regional New Zealand, and actually managed to make it back to the office today, which is a nice change.

But yes, as Charles said, I work in the research and development technical side, I’m also working on infrastructure projects. So right from, you know, design specifications, that sort of thing, to looking at older structures and ways we can extend their service life.

I’ve been with MARKHAM just over 10 years so had some good experiences along the way and, you know, testing projects, things I’ve worked on. So yes, back to you, Charles.

CHARLES: Awesome, that’s great.

So today’s learning outcomes for this session are,

- What are the challenges faced by marine concrete?

- And what can be done to meet these challenges in both new and existing concrete?

- And are there any other structures for which this is also relevant?

The session is approximately 15 minutes long, and at the end, we’re going to be opening the floor to questions, so please use the Q&A button at the bottom, the toolbar at the bottom of your screen, and put questions on as we go through it. What we don’t cover during the interview we’ll address in our Q&A session at the very end.

Right, let’s kick into it, Doug. Can you give us a quick overview of the topic, and what are the challenges of marine concrete? Give us some context here too.

DOUG: Yes sure thing, thanks. So I guess firstly let’s start with a description or an explanation of what a marine environment is. Now obviously differing code standards explain it slightly differently, but in general terms, a coastal environment is considered either on the shoreline and the water or up to one kilometre from the shoreline. And then there’s what they call a near-coastal environment, which is up to 50 kilometres from the coastline. So that’s basically where it’s recognised as a risk of, mainly chloride attack from the saltwater, and can occur either by physically, you know, wetting- drying or from airborne chlorides.

Obviously, that highest concern areas are in the, not actually in the water, but in that splash zone, where you’ve got variable moisture levels, you get that wet-dry cycling with tide changes, that type of thing, which is very harsh on concrete, that wet-dry cycle. And then obviously with a marine environment, with the seawater, there’s contaminants in the water, mainly the chlorides, and these contaminants get into the concrete, attack, the reinforcing steel, wreck its integrity, causing corrosion.

And unfortunately, this damage is not a gradual process; so once it starts, once it kicks off in the concrete… Once the rebar starts corroding, that’s not something that just slowly manifests over a number of years. It actually ramps up really quickly and accelerates, gets expensive really quickly.

So that’s the attack side of things. There’s also the operational challenges as well, so, you know, if you think about a wharf structure – It’s got traffic on it; whether that’s vehicle or pedestrian, it’s subject to loading, and there’s also you know, when ships tie-up, that type of thing, other marine vessels, there are always different stresses and loads caused by this. And, you know… obviously, the structures are designed to cope with these loads, and for, you know, their purpose. But obviously, over time there are the things like fatigue that gradually just wears the structure down, I guess. It subjects it to more of that attack. If that makes sense, Charles?

CHARLES: Yeah it does. It sounds terrible. It must be quite an expensive process to repair and replace these structures too. So what can be done about it?

DOUG: Yes it is. It is expensive; and it’s a bit of a sliding scale there as well, so the further down the damaged cycle or deterioration cycle you get, there is obviously a higher associated cost. Obviously, that’s fairly basic, but we do really need to understand that concrete itself, while it’s a very universal material, it’s a great building material – it does have one major flaw, and that is that it does let moisture in – you know, it’s a porous material, and it lets moisture ingress and, you know, move through it, move out of it and round it. And what happens is that that moisture by itself may not be a problem, but it does become a problem when it carries contaminants and things to the reinforcing steel, which attack the natural protection layer around the reinforcing and causes that corrosion cycle.

Now, obviously, there are ways to measure and see where that cycle’s at. The very best is to, you know, be taking regular condition assessments so you can pick up things like the chloride levels; or other non-destructive testing, and give you an idea of where that corrosion phase is at; what condition the rebar is in.

And then, there’s obviously visual signs that start to occur, like cracking of the concrete. So as the rebar starts expanding, that puts pressure on the concrete around it, and cracks it, and this eventually, as it gets worse and worse, leads to spalling and you get exposed rebar.

Now what’s really at the crux of this issue is that moisture movement, and we really need to immobilise that moisture. And that’s a well-accepted fact. Every engineer designs concrete to be as dense as possible, as durable as possible, to protect against this; but there is still that nano-scale or nano-pathways, if you like, that moisture and contaminants flow down.

So, immobilise that moisture and stop that those internal reactions, that corrosion, from happening. So basically we’re robbing that process of one of its main ingredients.

So yes, with that, as you can see on the screen here, we work with colloidal silica hydrogel technology. So this is, in essence, it’s either added into the concrete or spray-applied, and it reacts with the alkalis. In the main, that’s calcium hydroxides in the concrete pores and porosities; and it forms a hydrogel which stops that moisture migration. And essentially waterproofs the concrete. And along with that waterproofing of the concrete, you stop those contaminants from being able to ingress the concrete.

Now this is much like the original cement hydration reaction when concrete’s actually manufactured, so it’s it forms a calcium-silica-hydrate hydrogel; a bit of a tongue twister there! But it’s permanent, so once it’s formed, you can’t reverse that reaction and, you know, it is there for the life of that structure. So yes, is that making sense, Charles?

CHARLES: Yeah, good, that sounds a bit more positive to me! So that’s in the context of remediating existing structures. Is that right?

DOUG: Yes, so typically that’s where we get involved, so that’s obviously either when someone’s, you know, has been taking regular condition assessments and realise that you know, there’s need for preventative, proactive maintenance. If you’re just starting into that corrosion cycle. And then there’s obviously down the track when you might get some minor cracking start to appear, or even after repairs are being conducted; and the asset owner needs to keep that structure in that same condition as it currently is, you know, to get the best service life. So yes, in the main we are talking about existing structures.

But it’s also very relevant to new concrete. Obviously, if you can start right from day one, right from the readymix plant, so to speak, and stop that concrete being subject to attack by all – that reinforcing steel, I should say, being subject to attack from chlorides, right from day one. It gives you the best asset life, or best service life from the concrete. And there’s a couple of ways of doing this, either into the readymix concrete itself at the batching plant, as an admixture, or spray-applied soon after, to the concrete. So yes.

CHARLES: Very good! Yes, sounds like it would be relevant to more than just existing marine structures. Is that right?

DOUG: Yes it is. Obviously, we’re focusing on marine structures today, and they are a fairly common … you know, concrete deterioration is very common in these structures. Basically, I mean, it all comes back to the chloride in the seawater as we mentioned. that is generally where that’s most commonly associated with concrete corrosion. But there is other structure types, for sure, so things like bridges over tidal inlets, waterways, that type of thing; they can be subject to it as well. And then, you know, even a roading bridge structure in a high-volume traffic environment where you’ve got a lot of exhaust fumes, that type of thing; they can get increased carbonation, that’s formed from the carbon dioxide and moisture, and that mixes … forms an acid, and starts eating away at the concrete. And then there’s things like varying levels of acid attacks, so obviously softwater in potable water structures, that type of thing, and they obviously have higher acid attack in sewer environments. So yes, there’s a wide range of structures that, I guess, they’re subject to the same attack mechanisms because that moisture’s pulling the contaminants into the concrete and degrading it. But yes, as was mentioned, marine is a common one and generally deemed as a high-risk area.

CHARLES: Yes, very good. So what these structures being in quite sensitive environments such as sea life and waterways and so on – are the treatments safe to use, and is there a significant need to contain overspray, for example?

DOUG: Yes, good point. That’s a very valid concern, and with these colloidal silica hydrogels that we work with, they are a nil-VOC product; so they’re water-based and they don’t have any volatile organic compounds in them. So yes, overspray, that type of thing, when you’re spraying over waterways: for one, they’re not harmful to the environment or for marine life; and most importantly, they’re not harmful to the installers putting them in, or whoever may be spraying the treatments on.

And another thing to bear in mind, as we’re not actually introducing anything that’s not naturally found in concrete. So you know the main binder of concrete is calcium-silicate-hydrate. We’re putting more silica into the concrete, essentially to form more of that calcium-silicate-hydrate. So really putting more of the good things into concrete. We’re not putting something that’s foreign into the concrete. So yes.

CHARLES: Yeah, brilliant! So I guess the other thing is, how long … it comes up regularly, like … how long does it last? And does it need to be reapplied frequently? Along with that, what sort of warranties does it carry?

DOUG: Yes, awesome, good question. So if we just go back a little bit, to thinking about the reaction; once that colloidal silica reacts with the alkalis in the concrete it forms that hydrogel, that calcium-silicate-hydrate; that can’t be reversed, so it becomes part of the concrete itself. So in essence, it doesn’t need re-application. So once the structure is treated, there’s no benefit from a re-application; with the exception of a very highly acidic environment, where it may be wise to re-apply the treatment just to, you know, boost that surface and resistance. But in short, it is a one-time treatment. And with that, we offer project-specific warranties that are performance-based. So that’s tied to either chloride levels or the concrete impermeability – excuse me! – of the concrete structure. And with that – that is based … We are very project-specific, both as individuals and as a company, and we consider every project on its own merits, and so that’s the environment, the condition of the structure, and what repairs have been done, what’s, you know, what it’s used for. All those things. And then you know the geographical area. And give you, you know, a set number of years of performance warranty. We can say, Hey there won’t be any further deterioration, or There won’t be any elevation of chloride levels; or The impermeability will be maintained… whatever is the most relevant there. And we put a performance warranty. So that can be anything from 10 years to if it’s on a new structure, and right up to matching the design life of the structure.

So, and I guess another thing, in that context, there are structures we literally put our hands up and say, Hey, we’re not going to provide benefit to you here, and either the structures are too far gone. And hey, it’s most likely going to be demolished in a few years anyway. Or there might be some other reason when we’re prepared to walk away if it’s not something that we can actually help on.

CHARLES: Yes, excellent. Thanks, Doug. Did you have some projects examples you’d like to share with us too?

DOUG: Yes, sure, I think there’s a couple we prepared earlier here. So the first one is the Ohope Wharf up in Waikato. This is a recreational wharf structure, used for, you know, recreational fishing boats, that type of thing, as well as a very popular swimming spot for locals and tourists alike, and it had some repairs completed about 10-15 years ago and these had started to degrade again, it’s what’s called incipient anode formation. Basically, where you’ve got old concrete, new concrete and you get different electrical charges within that concrete, and it speeds up the corrosion process and causes, you know, further breakouts, often right beside the original repair area. So in short they re-repaired the wharf, and we’ve sprayed out certain portions of that wharf to protect that effect from happening again. And with that, provided a performance warranty that the, you know, there is no further damage for, I think it was, 25 years on, that one, I just can’t remember on top of my head, but yes, that’s a good example there.

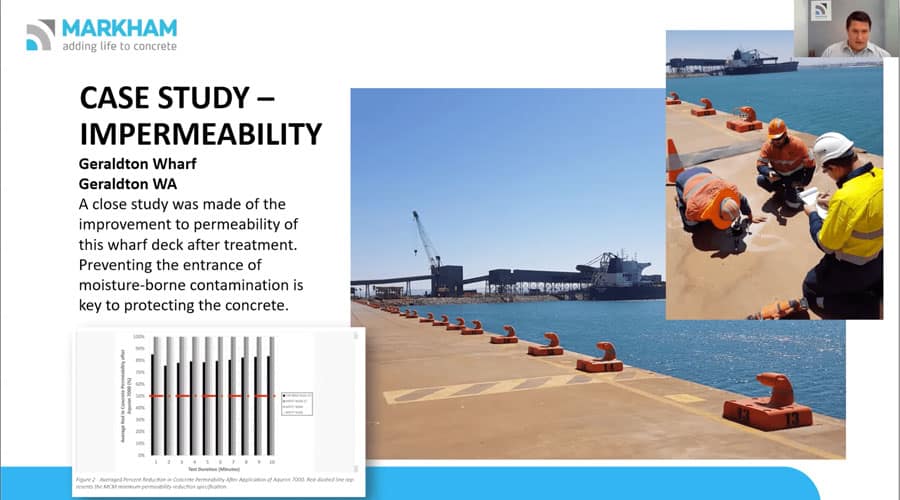

I think the next one there is the Geraldton Wharf. That’s over in WA and where the Port had to recognize it was an at-risk structure from, you know, in terms of service life; and there were some repairs that needed to be carried out on the structure and they wanted to keep it in that same condition. So we got involved with the engineering, with an engineering firm as well, and they put permeability reduction requirement on it, so they actually tested every work section down the wharf. So we ended up with a lot of data from that project. And on average I think our lowest result, you can see there, was 75%, but it was closer to 80% average and reduction in permeability. So that was, you know, along with, obviously, our performance warranties and other cross-checks to give assurance that the product was doing what we said.

So yes, that’s a couple there.

CHARLES: That’s really interesting! Thanks very much, Doug.

It looks like we’ve got a few questions together, so I’ll start with this one here.

“If I only need one part of the structure treated, will it show up against the untreated parts?”

DOUG: Yes, it’s a good question. It comes up a lot. So often there’s only one, you know, element or one, couple of cracks of the, on a structure that, you know, the rest of the structure appears to be in good condition. It is possible just to treat those areas. But what we do need to bear in mind is that that could be either the start of that damage manifesting itself in other areas, so it makes sense to keep the, you know, set a benchmark that the structure’s all protected at one time. And the other thing is often it’s, you know, we’re there, or the contractor is there, set up with all the access, and it’s not a lot more cost to treat the rest of that element, or the rest of that structure while we’re there; and you get that whole structure in that one condition.

So yes, hope that’s helpful.

CHARLES: Nice. The next one is, “What testing method would you recommend to determine the depth of chloride ingress in the concrete?”

DOUG: Yes, we mainly work with either coring or drilling into the concrete, taking dust samples, and measuring the chloride that way. There’s a couple of different ways, either waterborne or the acid method, I just can’t remember the exact name of it – to determine the chloride levels in the concrete. And we generally take them at either 10 or 15 mm increments down to the depth of steel; and that gives you a good picture of, One, how far the chlorides are in, and Secondly, what levels they are at the steel, which is really the high-risk area.

So yes, and I just, yes, I’ve seen that next question there, whether the reo itself has actually initiated. So there is a, there’s a recognised percentage of chloride in the concrete. I think it’s 0.05% of chlorides as a percentage of the concrete and that’s a recognised level where it changes from, you know, corrosion initiating to actually propagating, actually forming an expansive, you know, rust around the steel and starting to cause damage. So they generally, if you’re in that, you know, below that 0.05% there, it’s not high risk. But you can start to pick up a trend of where it’s hitting. Obviously, as I mentioned, right at the … the earlier you can treat a structure, the better. And even if it’s got no chloride ingress, it’s still wise to protect it because it is going to be subject to it at some point.

CHARLES: Now the next one is regarding the spray-on application. “How soon after the application can the concrete be exposed to water?” And it’s referring to the splash zone within tidal waterways.

DOUG: Yes, that’s a great question – thanks! So it’s a major benefit with these colloidal hydrogel treatments. In short, once they penetrate into the concrete and the gel’s formed, so that’s basically once the surface is … or gel starts forming, I should say – once the surface is touch dry you can apply water or the tide can come back up again and there’s no, that’s not going to adversely affect the product.

So we often work and – excuse me – on jetties and wharf structures where we can only access at low tides, and we’ve got a, you know, a few hours’ window to clean and spray the wharf, and then that tide can come back up again and it doesn’t affect the efficacy of the product. So that is a massive benefit

Some of the other treatments, yes, they do have, like, a set drying time, where it has to be dry and that’s not only just before, it’s actually for a few hours after the application as well. Whereas this is very … it can actually be applied to damp concrete, and then, once, as soon as it’s penetrated in, and it’s touch dry on the surface, it’s not affected by that saltwater coming back up again.

CHARLES: That’s good. Anything more to add?

DOUG: No, no, I don’t think so – that’s good. Thanks for those questions and, yes my contact details are there in the chat there, so yes, feel free, if there are any questions, to contact me there.

Our website’s got some very handy resources on it as well. Along with the contact form, so feel free to go there.

Otherwise, other than that now, it’s been good.

CHARLES: Excellent! That wraps us up for today. Thanks, everyone for coming on board. We’re going to be sending out an email with Doug’s contact details and also a link where you can request the recording. So have a great day and don’t miss out on our next session!

More about MARKHAM

MARKHAM are dedicated to providing innovations for concrete and construction. Focusing on concrete waterproofing solutions, penetrating concrete sealers and durability treatments concrete.

Invisible Strength – The media site for MARKHAM – Adding Life to Concrete.

At MARKHAM, we’re on a mission to transform concrete and construction. Our Purpose? ADDING LIFE TO CONCRETE.

From innovative waterproofing solutions to penetrating hardeners and sealers, our focus is clear: to reinforce concrete structures and make them withstand the test of time.

Newsletter

Sign up for email updates on the latest collections, campaigns and videos.