Unpacking the MARKHAM Flooring Installation Guide

Unpacking the MARKHAM Flooring Installation Guide

Webinar Show Notes

MARKHAM Flooring Installation Guide markhamglobal.com/markham-videos/5-rules-and-8-precautions

Concrete Floor Moisture Issues markhamglobal.com/challenged-concrete-moisture-control

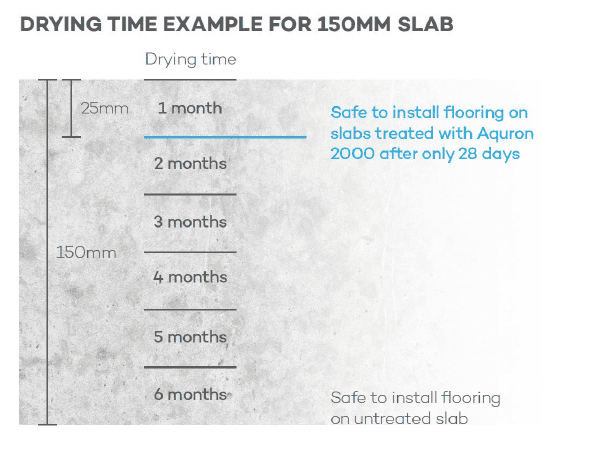

Drying time example for a 150mm concrete slab:

Learning Outcomes

- The WHY of concrete floor slab moisture issues under flooring.

- The WHY behind the MARKHAM Flooring Installation Guide, and its broader industry application.

- An advanced approach to concrete moisture control.

BRENDAN: G’day and kia ora, everybody! We’re very pleased to have you on board. On our webinar today, we’re unpacking the MARKHAM Flooring Installation Guide. Just a little bit of housekeeping, sorry we can’t show you where the toilets are or the fire escape. The presenters will be Henry Mitchell, he’ll be talking you through most of the technical side. He’s in the Napier office, I’ll give him an opportunity to introduce himself in a moment. And myself, it’s Brendan Stead in Bundaberg, Queensland.

You can ask questions. There’s a Q&A button in the toolbar at the bottom, which comes up if you float your mouse over that. We’ll be happy to answer the questions live at the end of the presentation if we’re able, or separate email if it’s too hard. But we would just like to put up here a little welcome poll, if you’d share with us why you’re joined today. While you’re doing that, Henry is going to tell us about himself. Go ahead, Henry.

HENRY: Yes, g’day Brendan! Thanks very much for the intro. Thanks, and welcome to everybody across New Zealand, Australia. Good to have you all on board here. I’ve been with MARKHAM for about nine years now. So flooring and moisture control and hydrogel treatments in concrete are very passionate subjects of mine. Together, we’ll tell you a little bit more about where we can help you today. Just waiting for those results to come back up and get a better idea, so we can make it a bit more informative. How are we looking there, Brendan?

BRENDAN: Looking good, Henry. We’ve got a strong emphasis on our architects and construction design professionals. Welcome everybody in that category, we’re very glad to have you. And a fairly even mix for the remainder.

HENRY: Yes, it looks good. Take it away, Brendan.

BRENDAN: So, the main learning outcomes here, as we’ve said, we’re unpacking the MARKHAM Flooring Installation Guide. We’re going to start with a bit of Why, about why concrete floor slab moisture issues exist in the flooring and why we’re even talking about it, and then the Why behind why we created the MARKHAM Flooring Installation Guide, which was in the context of our own products. But we’ve come to realize it’s got broader industry application, which is why we’re taking a bit of time to open it up for you today for its broader appeal. So forgive us if you hear us mentioning the products as we go through, but we’ll have a talk about that at the end as well. We’re going to talk about an advanced approach to concrete moisture control. Henry, walk us through the technical side.

HENRY: Awesome. Thanks, Brendan. I just want to remind everybody, chuck any questions in the question-and-answer box. Then moving on from what we’ve just heard from Brendan, we want to talk about why we have flooring moisture issues. A number of reasons. There may be existing concrete with a failed DPC underneath. You might have leaking concrete moisture coming through.

Predominantly those in the architect sector—which we’ve filled out the poll, thanks for that and welcome—this is the area we can help you guys. So, on average, it takes about 25mm per month to get below a safe level before we can lay flooring, carpet tiles, vinyl, anything on concrete. You might say well, that’s enough time. But that doesn’t start from the time that concrete is poured, that starts from when the concrete was last wet. So we all know, in our crazy speed up lives in business and construction programs these days, there’s never six months in the program after you have enclosed the building, to wait before you can put flooring.

The reason obviously why we have flooring moisture is that people put a lid on that, a curing membrane or something like that, traps all the moisture inside, and then they come to flooring. One, a lot of those wax-based cures are not compatible. So, the floor worker says, we have to grind that off and do some floor prep. Then suddenly, it lets all the moisture in our concrete and we have the moisture control it there and then.

So, we’ll talk about, a little bit further down the track, how we can help you with that. A little bit about why we have problems in concrete; basically because it takes a long time to dry out.

So, a background of the MARKHAM Flooring Installation Guide. This is nothing new, we’ve just done an updated form. You see the one behind there is the original AQURON 2000: 5 Rules and 8 Precautions, and we’ve got the new one in front which we’ll unpack in the next couple of slides. We just wanted to put it out there, there is a new version out there for you guys to have a look at.

Essentially, 5 Rules and 8 Precautions is something that we stand by here at MARKHAM with concrete. This is regardless of whether it’s hydrogel-treated concrete or not, these are just good building practices or good practices for installing flooring. For instance, surface absorbency, surface prep, the spread of adhesives, time since pour; things like that. You have to have absorbency in your concrete. You have to have a key for your carpets, and adhesives, and your vinyls to bond to. So, these are just things we send out with each application, just to be, I guess, educating the market on that. So those are the five rules, which we’ll send you a copy of that for those of you who do intend to have one.

Secondly, the eight precautions. So again, a number of, eight things or eight precautions to be aware of when it comes to concrete and moisture control. Say quality assurance, good trade practices, grinding. We all know, every floor layer out there would know more than me, because they’re the professionals, that you don’t lay floor coverings in direct sunlight because you can have issues. Wet lay, recommendations for non-adhering, grinding of concrete, things like that.

I mean, as I said earlier, regardless of whether you’ve got hydrogel-treated concrete, your flooring still needs a key, and if it’s too burnished up, it’ll need a grind, or it’ll need a sand for those adhesives to bond to the surface. So we just want to put that out there to help you guys along the way with that.

Moving on, we’ve talked about Why we get moisture and concrete issues, we’ve talked about the Why behind our flooring guide. Now we want to talk about the Why behind moisture control and hydrogel systems. This is where we can help you; we can save time and money. Save more time than money is a biggie for me, I like to talk to people about program savings.

You can see all the red highlighted lines in the little picture there. These are in a nano form, so you wouldn’t be able to see them by the eye. A concrete pour is about 50 nanometres, which a human hair is 100,000. So you can see the sort of pore size we’re talking about. The hydrogel treatment can get down to 10 nanometres. So when we spray-apply to the concrete, we get up to 150mm penetration into your concrete, transforming that gel and all those voids and porosities into another state. So it’s immobilized; its internal moisture control that can’t come out of the concrete. Therefore, saving your clients’ time and money in areas like program. So we can put this down at the time of preparing concrete, and you can put flooring down within 28 days of brand new concrete, overweighting that crazy six months we talked about earlier.

You can see the little comment there from Whitney Belkowitz, CEO and Founder of Intelligent Concrete out of Colorado. “One of the biggest problems in the industry today is that we’re solving problems with yesterday’s technologies. It’s time for a change.” So it’s about education. These hydrogels have been around since about ’85, but they are a new education to a lot of people. It’s about the internal treatment of concrete. Think of it like a spray-applied admixture if you’d like.

So hopefully that gives you a little bit of idea around the hydrogel working inside the concrete; we’re not adding anything foreign to concrete. Have you anything to add on that, Brendan?

BRENDAN: No, that’s good, Henry. Important to emphasize the point about immobilizing the moisture. A RH (Relative Humidity) test might still show a high moisture content, but it is in fact immobilized so it doesn’t move.

HENRY: Yes, correct. So the hygrometers, when you put them on the surface of concrete, it does throw up its arms and legs and say, there’s something in the concrete that looks like moisture. But the fact is that it’s another state; it’s no longer moisture. It’s not foreign to concrete, for engineers and people like that; it’s still helping them with curing the concrete. It’s feeding the hydration process, but it’s controlling that moisture in the concrete. So then you shouldn’t have any problem. That’s the Why behind the hydrogel solution, and why we like to talk to you guys about it. So we’ll move on to a couple of projects now we’ve successfully completed. Take this away, Brendan.

BRENDAN: Thanks, Henry. These projects we’re demonstrating just to give you a bit of an idea of the types of projects that this is very applicable to. But it is very broad in application, and we have been doing it for quite some years; we’ve got quite a lot of anecdotal evidence as well as the test results, you might say.

This project, I think it was in 2019, at Caversham South Primary School in Western Australia. We got involved early with this one, and we were able to assist with the curing, as well as the moisture control. That’s what Henry was talking about: saving time in your construction schedules, and it also saves money for curing barrier, the curing compound at the early stage. But you’re getting there and treating it right up early, before you do anything else to the slab, then you’ve got that benefit with hydration. But then at the end of the project, you’ve got the benefit with the moisture control. We stand by that with our performance warranty on that moisture control.

HENRY: That was a good point you just added about the moisture and the warranties. Tell us a little bit more about that, what do we include?

BRENDAN: Well, it does involve our quality control process, and we like to handle it. We have trained applicators, and it gives us that degree of control to give you an assurance that yes, that has been treated, and yes, we can guarantee that the floorings won’t fail due to moisture issues from the concrete. It’s a performance warranty. It’s not a like-for-like replacement warranty, which is a very important point.

HENRY: Yes, I’d like to add, I always say we’re not just giving you another pail of product. If there’s a problem, we’ll stand behind that with that 15-year. The difference is that it’s insurance-backed, so we can help you guys out and just take that risk right away from those clients.

BRENDAN: That’s excellent. This project here is different in as much as the treatment was applied at the end, not long before the floor coverings were applied. Classic old building. If you’re in Melbourne, you’ll be probably well familiar with it. It’s the old Dimmeys building, that clock used to be the Dimmeys logo. They preserved the facade and the clock, but the rest of it was gutted, and they put a Coles on the ground floor, with a new slab. We didn’t get involved at the site till the end of the project, and we worked with the flooring applicators to put the treatment in.

So just to emphasize that point that we can work with the construction team or we can work with the flooring applicators, we’re very happy to do so. We’re not against you, in that sense. Sometimes it seems like a bit of a conflict of interest, but we are happy to work with the flooring teams.

HENRY: Yes, that’s correct. So I’m just moving on to a couple of projects a little bit close to home for me. So this is the cool new Nelson Airport that’s been probably in operation, I think it was before lockdown, so about a year. They built it in two halves, obviously to keep the old one still functioning while they built the new airport beside the new terminal. And they built a raft, poured a raft slab, put all their build in place, and then they came through about six weeks before opening and poured a topping slab.

If you guys remember back to the early slides where we talked about the 25mm per month, obviously they had a 150mm topping slab here that they wanted to put flooring down within a couple of weeks, so they could open this airport up and then start on the second half. If they hadn’t had that moisture control and cure at the time of pour on that topping slab, they would have had to wait that long period.

So we helped them obviously by installing the hydrogel treatments, and they can install flooring within 28 days of brand new concrete. So we obviously helped them with program savings there, but also helped them with cost savings as well because time is money. So that’s a pretty cool example of where the moisture control really worked.

Just the last one here, which is actually a local Kmart, so we’re very pleased. In Napier here, we just had a local Kmart opening. Especially my wife, we seemed to go across to the Hastings one, which was about half an hour away, once a week. So we could have one five minutes from home. We actually walked there this morning.

We cured and moisture-controlled this whole slab for the Kmart store, again, helping them with their flooring install; all of their internal flooring. There’s obviously a vinyl-backed tile, vinyl tile, so we cured and moisture-controlled that one. So it’s a great little example where we can help out in the local economy as well.

That’s a bit of a wrap on some of our projects, a little bit about how we do it and why we do it. If you have got any questions there, you can ask us now, chuck it in the questions box. I see there’s about 15 people in there still, so thank you very much.

We’ve got one question there. Awesome question there. Can the product be applied to old concrete? Yes, it can. It’s a penetrating treatment. So again, as long as your concrete is raw concrete, if moisture can get into your concrete, the AQURON treatments can get in there too. So we can get there 150mm+ penetration right in there. We know this from working a lot in a little bit of a different industry, but in the marine environment to stop salts and chlorides get into rebar. So we can spray-apply it. I hope that answered your question.

Any other questions out there, we’ll just leave it open for a little bit longer. We’ve got one more. Is this product suitable for small residential projects using tiled floor finishes? Anywhere where you’ve got floor finishes, we can help you with moisture control. We generally stick to the commercial area market; we don’t do residential. But we are a very project-focused company as well, and we would like to be able to come up with a solution that could help you and your project on that. So hopefully that answers your question.

BRENDAN: Yes, we might make contact with that one directly after.

HENRY: Yes, definitely. What have we got, have got anything else? Is it just for floors or can it be used for precast walls? Another good question. So predominately, in this webinar, you’re talking about curing and moisture control on floors. But the hydrogel treatment doesn’t matter whether it’s a vertical surface or a horizontal surface, it still works inside the concrete. So yes, we can waterproof precast walls.

When you talk about precast, it comes a little bit of a different game. It would probably more work down the line of some of our new concrete admixtures, which we can talk about; we can send some information. We’ve got admixtures here; they waterproof the internal matrix and seal the vertical surface as well. So a little bit of a different game, but yes, it can be used on precast walls. So we’ll just leave it open for one or two more.

BRENDAN: Did you want to have a word, Henry, about including it in specifications?

HENRY: Yes, definitely. For those that are still on board, we work from design through the installation. So we’ve got all the Masterspecs, all the Natspecs; we can project the right specs for you guys for your project. We like to be able to chat and get an idea right at the start. We’re a risk-averse company. So we don’t just go out there saying holus-bolus, this is what you need. We work out, take into account your program, take into account the scope, take into account the use of the building, and that sort of thing.

Last question there is a good one actually. Do you have a solution for a finished building, and how much damage occurs during the remediation process? So I guess … we can post-apply it towards the end, before flooring, if I make myself clear. But it is obviously different. The cost goes up because where there’s flooring prep, we have to do the likes of … mask-off all your windows, aluminium your finishes, that sort of thing. So there’s a bit more to it. But yes, we can definitely install it before flooring.

How much damage occurs? Well, all the people that work for us, our applicators are trained applicators. That’s managed through our head office here in Napier, New Zealand for New Zealand, and then in Australia, we’ve got project managers on the ground there, in their head office is in Sydney. We would make sure that there’s no damage left, so we’d leave the finishes as they were before we started. But ideally, it’s best to get onto it – spec it in your project at the documentation stage, get on to our spray-apply at the time of new concrete, and you’ve got your problem done. Temperature limitations?

BRENDAN: Just looked up the tech datasheet on the temperature limitations, Henry!

HENRY: Yes, there’s not much there.

BRENDAN: It can’t apply at less than 2.8 degrees Celsius.

HENRY: Yes, and the other end of the scale is where it’s ridiculously hot, and humans wouldn’t be able to live in the conditions. Obviously, we work throughout Australia, and I know the boys in Perth over the last few months have been hitting the 40s. It’s more about their health and safety than the product’s health and safety, making sure they’re hydrated and that sort of thing. So no limitations around the product applications.

In that, it does work well with freeze-thaw, because we’re transforming the moisture into a different state, it can’t freeze. So in real cold applications, we can’t put it on below two degrees. But if we put it on before that temperature drops, obviously it’s going to protect your concrete.

Another one there. Do hydrogels work with just concrete or other machine products like clay bricks? It has to be cementitious for the hydrogel to work in there inside the concrete, so it just forms more of the CSH process. Clay bricks, that’s where we’d step in as a risk-averse company and say no, and point you in the direction that you should go. Anything to do with bricks, you’re opening yourself up a little bit. Because you’ve got grout lines, you’ve got potential movement, potential cracking, and moisture coming through as well as out of the concrete. So we would tend to steer away from masonry and clay bricks. Hopefully, that answers your question.

BRENDAN: I want to just add a comment on that, Henry. We do other products for vertical masonry surfaces, which is a slightly different field than what we’re talking about today, just not to be confused. But not for flooring moisture.

HENRY: Yes, awesome. Okay, so I’d just like to thank everybody for joining today. Hopefully, it’s been informative. Thanks, Brendan, for your input. Thanks, everybody out there. If you’ve got any questions, you can email myself or Brendan, we’ll help you out and try to help you on a project, whether it’s early on or post … end of the project. Thanks very much, everyone. We’ll see you later.

BRENDAN: Thank you, everybody!

More about MARKHAM

MARKHAM are dedicated to providing innovations for concrete and construction. Focusing on concrete waterproofing solutions, penetrating concrete sealers and durability treatments concrete.